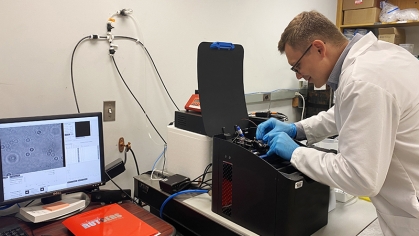

Shishir Chundawat and PhD student Aron Gyorgypal create a monitoring toolkit able to speed up biologic drug production

Continuous biomanufacturing has been a hot topic within the pharmaceutical industry in the past decade, though current technology has still not allowed the industry to fully adopt this process for the manufacture of complex biologics, such as monoclonal antibodies; a large group of immunotherapies. However, Rutgers’ Associate professor Dr. Shishir Chundawat, and Ph.D. Candidate Aron Gyorgypal, who has been working within the continuous bioprocessing thrust of the chemical and biochemical engineering department has invented a new analytical toolkit able to monitor a key quality attribute of glycoproteins. This key innovation promises to allow for monitoring and control of biologics during the manufacturing process and could allow for faster screening of drug candidates as well.

Quoting Aron Gyorgypal, “Our system will allow complex biologics to be produced with molecular-scale precision, basically, we are able to check the drug’s quality rapidly, multiple times during the process to know for a fact that the biologic that is being produced is following the preferred reaction trajectory that meets both regulatory and industrial quality control expectations.”

Why is this important? Well, federal regulators have been hesitant to allow wide-scale production of biosimilars because of quality and safety concerns. “The FDA will have a lot more confidence about a drug product that has similar advanced analytical tools being used for monitoring its manufacturing process,” Chundawat said.

The publication can be found at: https://pubs.acs.org/doi/10.1021/acs.analchem.1c05396